Gate valves

Person in charge of your inquiry:

+48 12 255 85 01 energiaigaz@cptrade.plGate valves

Stream Flo offers full bore crown gate valves with the ability to regenerate without dismantling from the pipeline along with long life seats. Their use is very wide ranging from: wellheads, Fracking wellheads, ESD systems, choke reduction valves and kill manifolds. Valves can be equipped with one or two-way pneumatic or hydraulic actuators with manual control and protection system with closed or open safety position.

Types of produced valves:

Crown gate valve model A

Available from 2 1/16” to 4 1/16”

Pressure from 2000 psi to 5000 psi

Flow direction – unidirectional

Cast body

Expanding gate design

Mechanical seal

Stem seal can be supplemented

Gate death space is isolated from the flow

Crown gate valve Model B

Available from 5 1/8” to 6 3/8”

Pressure from 2000 psi to 5000 psi

Flow direction – bidirectional

Cast body

Split gate design

Parallel gate valves are equipped with springs which are responsible for self-cleaning the valve and its sealing even at low pressure

Stem seal can be supplemented

Rear seal allows seal or stem seal to be replaced

Crown gate valve model Sl-2

Available from 2 1/16” to 9”

Pressure from 3000 psi to 15000 psi

Flow direction – bidirectional

Forged body

Slab gate design

Patented two-piece seal system

No access ports on the body

Pin securing the stem from excessive torque

Rear seal allows seal or stem seal to be replaced

Certified as SSV

Certificate API 6FA

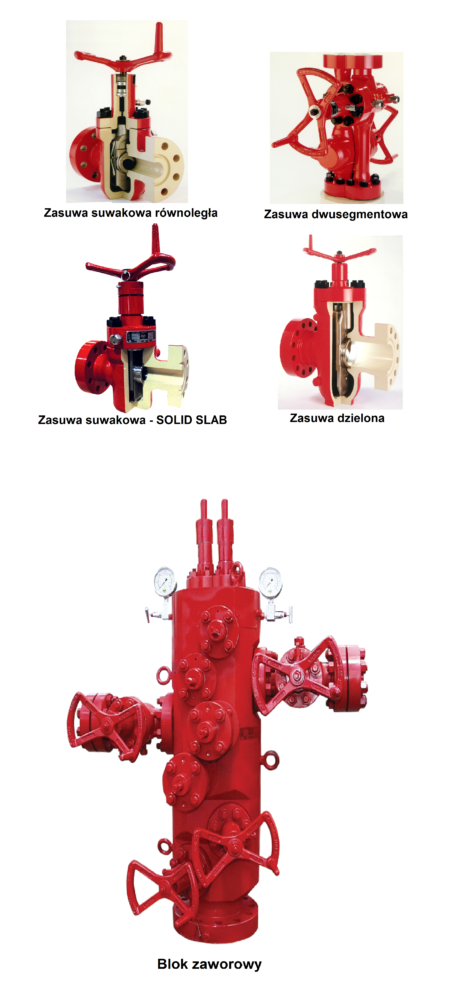

Structures of manufactured crown gate valves:

Parallel expanging gate

Thanks to this solution, we obtain an extremely high mechanical force of the sealing in the seat which acts simultaneously on both sides.

Two segment gate

The gate body is constructed in such a way as to allow passage through the pipe to the second gate.

Solid slab gate

It uses a bidirectional construction with a floating slab that moves parallel to the seat.

Split gate

This bidirectional valve is fitted with a metal-to-metal seal between the slider and the seat and the seat and body. The seal is reinforced by an auto-seal system.

Kill mainfold

Depending on needs it contains all the necessary equipment and connections for the application.

Body design:

Cast

Forged

Composite

Applied for applications:

Sweet / sour oil and gas

Forced extraction system

Injection

Thermal

Electric submersible pumps

Surface valves (SSV)

Gas storage

Working parameters:

Pressure from 2000 to 20.000 psi

Temperaturę from -60° to +345° C

Bore sizes 1 13/16” to 9”

Trims depending on the medium:

Sweet /General service

Sour/NACE

CO2

Deposit water

Corrosion resistant alloys

With protective coatings

Clad with other metals

End connections:

API flanged ends

Threaded ends

Clamp-hub ends

Union

Specyfication compliance:

ISO 9001

API 6A @Q1

NACE MR0175